Manufacturing efficiency and supply chain enhancement are key goals for most industrial enterprises today. In this scenario, the optimisation of manufacturing demand with advanced analytics is deemed essential for driving higher productivity, lowering wastage, and enabling higher operational efficiencies for companies.

Based on data-driven insights, enterprises can deploy analytics for setting goals and empowering self-management of performance at the operators’ end. They can identify the best practices for achieving growth while designing their formal working procedures accordingly.

They can also enable the empowerment of front-line personnel with regard to enhancing overall training, collaboration, and communication, especially by using varied productivity tools for this purpose. Manufacturing entities can use advanced analytics to generate higher efficiency in production along with enabling more agile production lines, assets and supply chains with data-based support and decision-making.

Real-time and historical operational data can be leveraged for improving processes and ensuring higher standardisation to save both time and costs. At the same time, this will also help personnel detect potential risk sand variability, thereby bypassing errors that can prove costly in the long run.

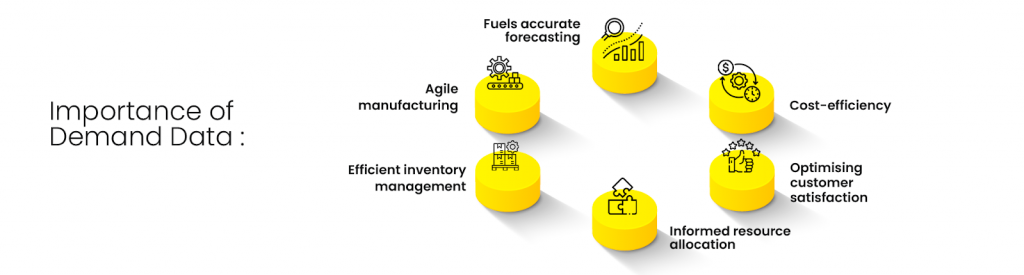

Demand data is crucial for manufacturing enterprises at multiple levels. Here are some points worth noting in this regard.

Hence, as can be seen, demand data is the lifeblood for leveraging advanced analytics towards taking better business decisions. Let us now take a closer look at data integration and why it matters.

If manufacturing enterprises have to rely on data-driven insights and use analytics, then data integration is a must. Here are some pointers on the same.

Using robust data platforms and focusing on data integration are crucial tasks for manufacturing entities. It is essential for ensuring the accuracy and quality of data that is being used for analysis and insight-gathering. Advanced analytics can be used effectively to forecast demand for manufacturers. Here’s examining the same in more detail.

Using advanced analytics for demand forecasting comes with its fair share of benefits for manufacturers. Here are some of them:

Manufacturing demand can be suitably optimised by leveraging advanced analytics. At the same time, manufacturing enterprises can manage inventory better and streamline product planning with the help of these insights.

Manufacturing analytics can be adapted to different manufacturing environments. They may enhance the quality of the end product of the company while also enabling data-based product optimisation, identifying defects or errors, and also evaluating consumer feedback and other buying trends.

Optimising manufacturing demand comes with several advantages, including enhancing overall equipment efficacy, lowering delays in production, enhancing the effectiveness of equipment, lowering the chances of breakdowns, and also tracking equipment performance and availability. It may also help in scaling up overall quality.

Optimisation goes hand in hand with just-in-time (JIT) manufacturing. This is sometimes known as lean production/manufacturing. Instead of supplying consumers and producing goods from stocks, JIT systems emphasise on the production of the exact amount required when consumers need the same.

Analytics can greatly enhance relationships with suppliers. Some of the advantages include easy tracking of supplier performance and tackling issues along with boosting trust and communication throughout multiple channels. This is enabled through easier demand forecasting, avoiding overproduction and streamlining timelines and supply chains accordingly.